GreenJOBS Project focuses on repurposing end-of-life coal mines, one of the sectors most affected by the transition, by deploying emerging renewable energy and circular economy technologies to help develop a renewable-based energy sector, promote sustainable local economic growth and maximise the number of green and quality jobs for former coal mining workers while addressing their training and re-skilling. It will also contribute to the decarbonisation of energy-intensive industries by supplying them with green hydrogen.

GreenJOBS will provide mining companies with two innovative business plans: a Virtual Power Plant where the energy produced will be sold to the grid or used to power electro-intensive industries or companies with constant energy consumption located close to mines, such as aluminium factories or green data centres; and a Green Hydrogen Plant where renewable hydrogen will be produced by electrolysis of mine water and electricity from renewable sources.

The unconventional pumped hydro energy storage using dense fluids proposed in GreenJOBS has two innovative values compared to what has been already proposed at both European and worldwide levels: firstly, it can operate in flooded mines, mainly eliminating the costs of pumping mine water in general and water used for geothermal in particular, something that is not feasible with other energy storage alternatives such as Graviticitry; secondly, the use of dense fluids allows providing density differentials between the fluids and, the greater the difference, the more efficient the system will be.

GreenJOBS is the first European/worldwide project that will include circular economy technologies to recycle fine coal waste directly addressing and complementing the specific needs of the project: (1) the development of soil substitutes to restore waste heaps before installing photovoltaic/wind; (2) the development of dense fluids for the unconventional pumped hydro energy storage; and, (3) the recovery of rare earths, critical raw materials for the EU, enabling the project’s vertical integration into the clean energy value chain.

GreenJOBS will include for the first time a detailed assessment of job creation potential per MW installed (MWh-MW for storage capacity and MW of electrolysers capacity for H2) for the project’s renewables, as well as for the project’s circular economy technologies based on their production capacity, both for commissioning and operation. It will also address the skill gaps of former coal mining workers and develop a framework for training and re-skilling, thus protecting the most vulnerable workers to the transition.

To maximise the proposed outcomes, GreenJOBS will leverage five main competitive advantages that coal mines posess compared to different environments:

MINE WATER

Geothermal energy is a renewable source that harnesses the heat from inside the earth, in our case, through the water that floods the mines. From a certain depth, the temperature of the subsoil is constant regardless of the season. Thus, a constant and accessible energy source is available all year round, just a few metres away from us. The water temperature alone is not useful for heating and cooling. However, it can be processed in a geothermal heat pump, which transforms the energy from low to high temperature, becoming suitable for these purposes.

On the other hand, mine water represents an essential raw material for producing green hydrogen by electrolysis. This process needs up to 18 tonnes of water – not counting losses – to produce one tonne of hydrogen. Water treatment systems typically need about two tonnes of impure water to produce one tonne of purified water. In other words, one tonne of hydrogen needs not nine, as usually stated, but 18 tonnes of water. If losses are considered, the ratio is close to 20 tonnes of water for every tonne of green hydrogen.

Finally, mine water will also be an essential input during the flotation process to obtain the rare earth concentrate produced in the mines from fine coal waste. The concentrate will be sold to hydrometallurgical plants, where a mixed rare earth precipitate will be obtained.

The main barriers to develop new renewable energy production facilities are grid access capacity and connection to transmission and distribution networks.

To overcome the first barrier, GreenJOBS will disseminate the importance of governments regulating the procedures for granting all or part of the grid access capacity of grid nodes affected by coal power plant closures to new renewable energy generation facilities that promote the economic and social recovery of Just Transition areas, with a particular focus on employment, business development and fight against depopulation (Just Transition Nodes).

As for the second barrier, mines are usually connected to the grid via overhead lines. They are typically connected to medium voltage lines through substations. The lines enter directly into the substations equipped with metering equipment, transformers, and other protective equipment. In this way, they can be easily adapted to inject electricity into the grid. Moreover, these connections facilitate the intallation of electrolysers for producing green hydrogen.

Extracting coal generates vast amounts of residues during excavation, including overburden, interburden or waste-rock. These large amounts of extractive waste from excavation generated at extraction sites are managed on heaps. Extractive waste heaps are usually reshaped to the angle of natural repose, depending on the extractive waste characteristics, resulting in a geomorphic shape that, either in itself or after placing a cover, provides long-term stability and adequate stability protection against wind and water erosion.

Given that the areas occupied by waste heaps after many years of exploitation are usually huge, it is possible to consider different rehabilitation and subsequent user actions. GreenJOBS proposes to use these areas for renewable energy generation: photovoltaic/wind. This will require the application of rehabilitation techniques that will facilitate the geotechnical stability of the renewable energy generation structures in addition to restoring the land.

Unconventional pumped hydro storage has a smaller footprint and higher energy density than conventional pumped hydro energy systems. The system uses a high-density fluid and allows for different configurations where upper and lower reservoirs may be at the same elevation, for example, on the surface above an underground mine.

By employing high-density fluid, a more compact pumped hydro energy storage system can be achieved. For a given reservoir or tank volume, the energy storage capacity is proportional to the fluid density. For example, when the high-density fluid has a density of 3x, the system’s energy storage capacity is 3 times that when water is used. It is due to the mass flow rate is about 3 times more than that of water. Alternatively, the system can produce the same amount of energy output using less volume of fluid and/or less height differential between the upper and lower reservoirs. Thus, coal mines’ deep infrastructure is very suitable for designing a system to satisfy output requirements: large height differentials and very deep galleries that eliminate the need for a bottom pressure vessel, with pressure relatively stable and close to that due to overburden.

Significant amounts of fine coal waste are stored in landfills, a residue from coal processing. GreenJOBS will valorise this residue through:

a) Recycling into dense fluids: Unconventional pumped hydro energy storage system employs a high-density fluid, such as a slurry, which has a density greater than water. GreenJOBS will test the feasibility to use fine coal waste from the three case studies to develop a new low viscosity high-density fluid in which the liquid is fine coal waste suspended in water.

b) Recycling into soil substitutes for restoration: Large waste heap areas have to undergo rehabilitation to achieve the geotechnical stability of the renewable energy generation structures, but, in addition, the land has to be restored. GreenJOBS will test the feasibility of developing artificial substitutes for soils suitable to several plant communities, addressing coal mining waste heaps. To achieve this goal, blend feasibility tests of fine coal waste from one of the project’s case studies and wastes from closely located agricultural industries, coal-fired power plants, and water plants will be developed.

c) Rare earths recovery: According to the United States Department of Energy (2017), both coal processing waste and ash residues have received attention for the economic value of the rare earths they might contain, particularly heavy rare earth elements. Data appear to show that cleaning enriches some rare earths. Praseodymium is the only rare earth that is consistently enriched by at least a factor of four. However, the enrichment seen at the finest particle size occurs for all rare earths. Further, it supports the observation that the rare earths occur in considerable measure as finely divided material in coal and coal by-products within preparation plant streams. GreenJOBS will explore at the laboratory level the possibility to concentrate mixed rare earth oxides based on their high density, paramagnetic and non-conducting properties from the case studies’ fine coal wastes.

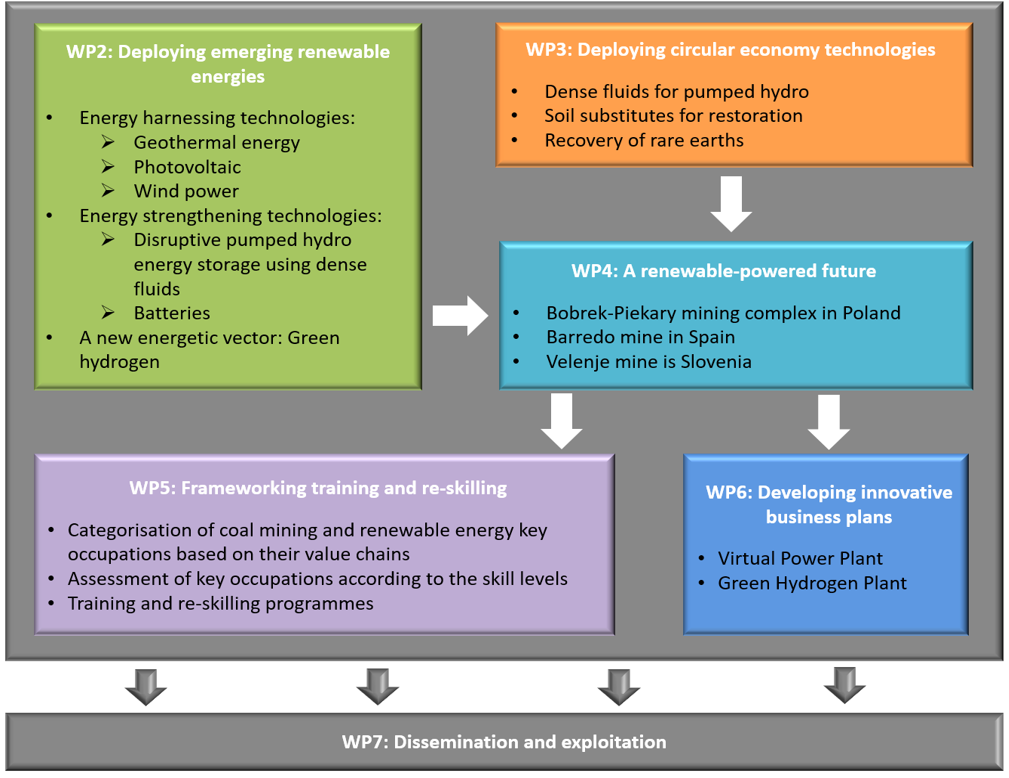

The proposal is structured into seven Work Packages (WP) to develop the project’s methodology:

Apart from WP1 that addresses the project’s coordination and management, the rest are presented here:

In this work package, all the coordination tasks are included: overall technical coordination of the project; organisation and management of meetings; distribution of technical data and information among partners; preparation of minutes and integration of reports; and administrative issues, including relations with the European Commission.

First, this work package will analyse the technical specifications, cost data and operational constraints and develop a detailed assessment of the job creation potential per MW installed, for commissioning and operation, for the deployment of energy harnessing technologies. In this way, coal mining companies will be able to assess the available renewable resources, as well as identify which options are optimal in terms of cost-benefit and employment for the conditions in the study area.

Second, to maintain a competitive supply of electricity, energy storage is necessary. Storage can absorb excess electricity generation and re-inject it later, effectively reducing curtailment due to excess generation or demand constraints. It can do this both in a market or in a vertically integrated environment. This work package will therefore undergo an equally detailed analysis for the deployment of the selected energy strengthening technologies needed to support the available renewable resources, as well as a detailed assessment of the job creation potential per MWh-MW of storage capacity.

Third, this work package will undergo a detailed assessment of a new energetic vector: Green hydrogen, produced by the electrolysis of water and electricity from renewable sources. It is a clear alternative to selling renewable energy to the grid or to power electro-intensive industries with constant energy consumption. Again, technical specifications, cost data, and operational constraints will be analysed. A detailed assessment of job creation potential per MW installed or per MW of electrolysers capacity installed for commissioning and operation will be developed.

This work package will develop a detailed assessment of circular economy technologies based on the valorisation of fine coal waste, a by-product of coal processing often stored in landfills, which directly addresses and complements the project’s specific needs. As in the previous work package, technical specifications, cost data, and operational constraints will be analysed, and job creation potential based on the production capacity for commissioning and operation will be assessed.

GreenJOBS will use three case studies to plan site-specific deployments of the emerging renewable energies and circular economy technologies addressed in the previous two work packages, to develop a renewable-powered future for these areas, focusing on the flexibility of the energy systems and the complementarity of circular economy technologies. Flexibility is the leading enabler of renewable energy integration. It can be defined as the ability to cope with the variability and uncertainty introduced by renewable energies on different time scales, from the very short to the long term, avoiding energy curtailments.

Case studies were selected to cover main types of underground coal mining: (1) underground longwall mining in Poland with sub-horizontal hard coal seams; (2) underground sub-level caving in Spain with sub-vertical hard coal seams; and (3) underground longwall top coal caving in Slovenia with one of the thickest known lignite seams in the world.

In this work package, GreenJOBS will address the skill gaps of former coal mining workers in the three case studies to establish the workforce’s training and re-skilling needs to facilitate the development of the envisaged business alternatives.

A feature of coal mining is that many of the technical skills required vary little between countries and that some of the skills required for operating and maintaining coal mines can be adapted to the operation and maintenance of renewable energies.

Based on the experience gained in the three case studies where specific deployments of emerging renewable energy and circular economy technologies were considered, this work package will develop an innovative business plan for each business alternative considered within the case studies: one for a Virtual Power Plant and one for a Green Hydrogen Plant.

This work package concerns the activities to be carried out to support the communication and dissemination of GreenJOBS knowledge and results to the entire European coal industry, the energy-intensive industry, the European Commission, academia and coal regions in transition (including regional authorities, civil society and other stakeholders), as well as to maximise the exploitation of project results by end-of-life underground coal mines.