1.- Comprehensive overview of the project

A state-of-the-art was developed to provide a comprehensive project overview.

D1.2 Comprehensive Overview of the Project

2.- Deploying emerging renewable energies

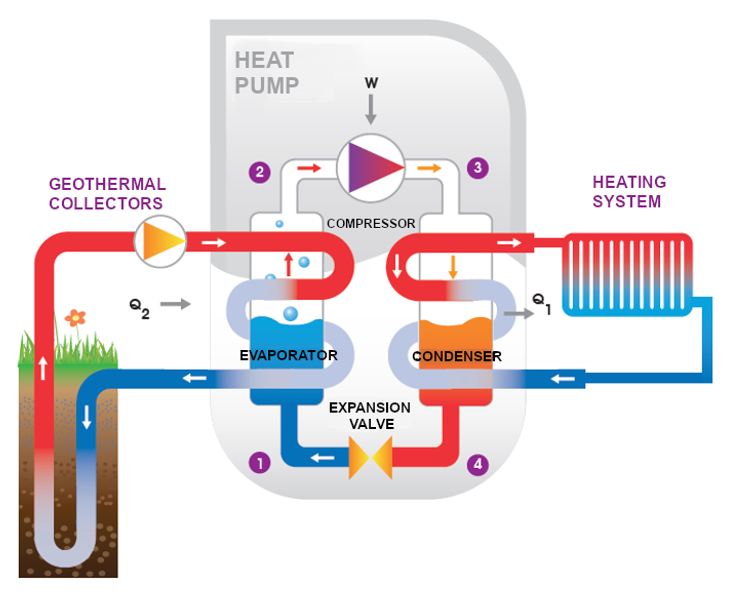

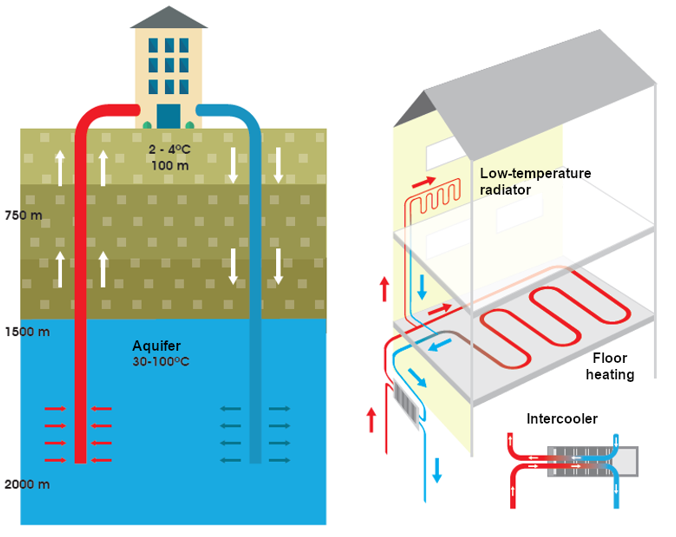

2.1.- Geothermal energy deployment

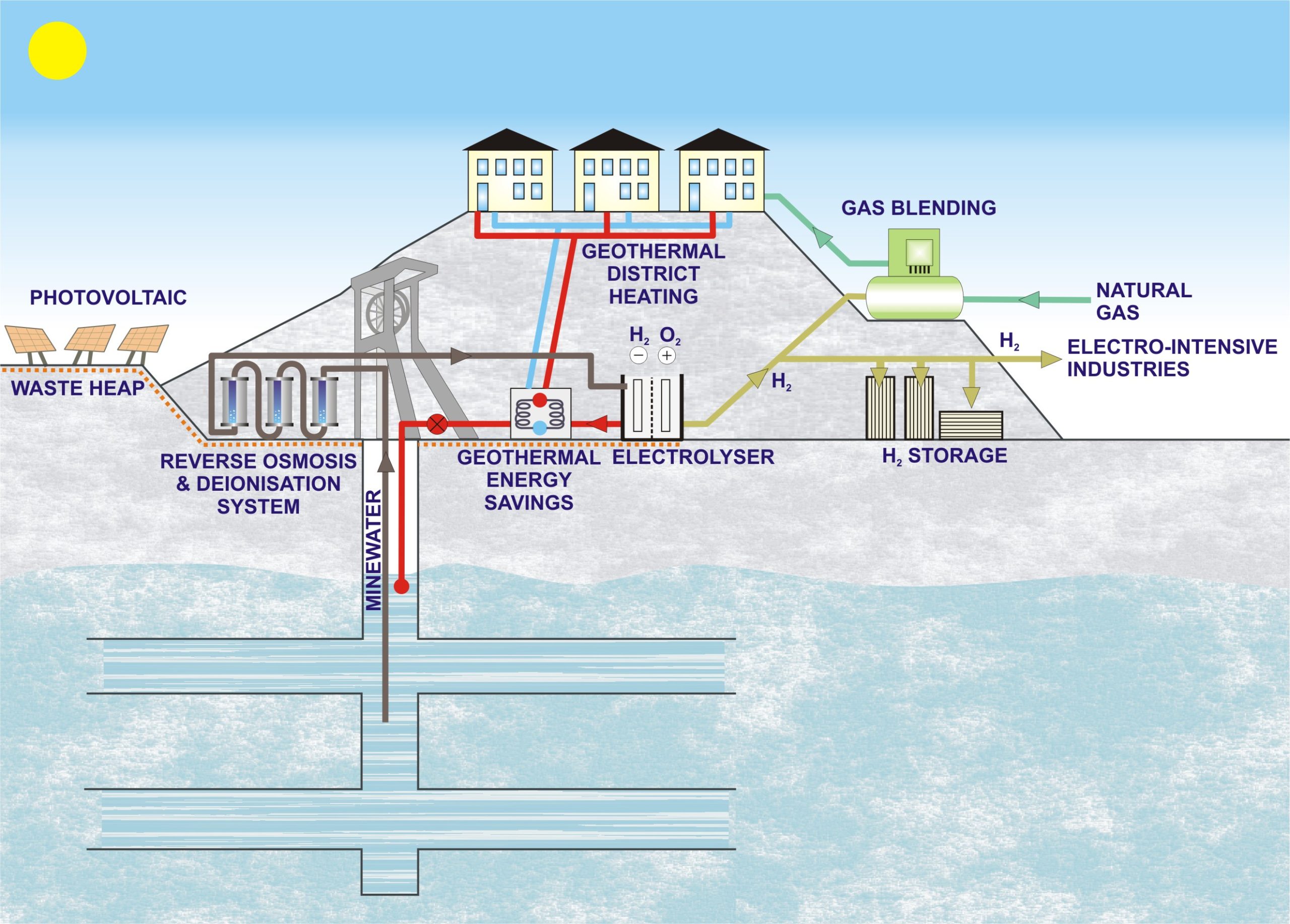

The characteristics of geothermal conditions worldwide and in Europe are discussed. The analyses covered the geothermal energy market and identify technologies for geothermal energy recovery, such as direct dry steam plants, flash steam plants, binary cycle power plants, and hydrothermal spallation drilling technology. The report also discusses the use of geothermal energy in mining, including closed-loop and open-loop systems.

Considerations relating to the energy system for geothermal energy deployment in mining areas and the value chain were prepared. These highlight the potential benefits of using geothermal energy, such as reduced costs and emissions, increased energy security, and job creation. The report also discussed the challenges and barriers to geothermal energy deployment, including geological and technical risks, regulatory frameworks, financing, and public acceptance.

This task concludes with a discussion of best practices for geothermal energy deployment in mining areas. It highlights the importance of collaboration among stakeholders, including government, industry, and local communities, and the need for innovative financing mechanisms, such as public-private partnerships, to overcome the barriers to geothermal energy deployment.

D2.1 Geothermal energy deployment

The lessons relevant to GreenJOBS from the deployment of geothermal energy can be summarised as follows:

- End-of-life underground coal mines present a unique opportunity for geothermal energy production. These mines have already been excavated to great depths, so they have access to the earth’s natural heat. By repurposing the existing infrastructure, it is possible to create a geothermal power plant that produces electricity and heat with minimal environmental impact, as far as the shaft is close to the potential clients.

- Choosing a geothermal technology requires consideration of environmental aspects because the quality of surface waters to which loads of pollutants could be discharged together with industrial sewage or mine water is very low. For this reason, when choosing technologies based on an open-loop system, an environmental analysis should be carried out to limit the negative impact of mine water on the environment.

- Geothermal energy is a reliable and constant source of energy that can power homes, businesses, and industries for decades. This makes it an attractive option for countries looking to reduce their reliance on fossil fuels and increase their energy security. Moreover, providing renewable energy, guaranteeing savings in energy costs and maintaining and replacing components, etc., may be attractive to potential consumers.

- The process of extracting geothermal energy from coal mines involves pumping water from the mines and using the heat to generate steam, which can then be used to power turbines and generate electricity. The need, in many cases, to pump water regardless of the presence of a geothermal installation helps increase the geothermal project’s financial outcomes, as pump costs can be considered sunk costs.

- Due to variations in the quantity of pumped water, temperature and quality, geothermal system mining areas should be selected after a feasibility study. In case of low-quality mine water, installing a heat exchanger inside the underground reservoir in a closed loop system is recommended. If the mine water quality is good, it is preferable to install an open-loop system.

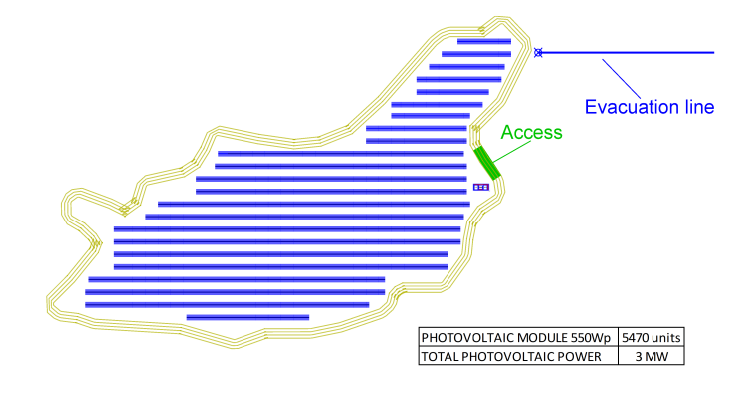

2.2.- Photovoltaic deployment

Photovoltaic technology is one of the fastest-growing renewable energy technologies. However, as any technology, the deployment embeds a number of challenges, boundaries and cons. Difficulties related the lack of raw materials, the increasing prices of PV cells and electronic devices; or related to important requirements to cover, such as land needs, environmental regulations or the “Do No Harm principle”, among others, may lead the depreciation of some investment initiatives.

Thus, a deeper knowledge of such boundaries may help to figure out how to reduce or overcome such difficulties during the project definition, and to define the priorities in the technological development. For example, identifying most appropriate locations where to elaborate consistent viability analysis, adapting the technology to the site. To do that, an exhaustive revision of the different elements conforming a solar PV system is conducted here. Also, main typologies and features of coal mines have been described, defining a generic characterization of such facilities to identify and highlight those singularities of mining areas which could create competitive advantages as potential locations for PV installations.

Taking this into account, two different but complementary scenarios have been identified and drafted as potential use cases. The characterization of these use cases and the definition of specific operational requirements will help to reinforce arguments in favour of using coal mining areas as proper locations of PV systems; but also, to select best technologies to better fit the aforementioned requirements.

The lessons relevant to GreenJOBS from the deployment of photovoltaic energy can be summarised as follows:

- The repurposing of end-of-life coal-related assets and infrastructure at coal mines for photovoltaic (PV) installation plants offers a promising approach for recovering unproductive lands and generating renewable energy.

- PV technology is highly modular and ranges in size from small solar home kits to systems with capacity in the hundreds of megawatts, offering a democratised electricity production.

- Due to the huge variety of features and types of mine sites, a multi-criteria reasoning analysis should be performed to determine the best technology by scenario.

- Leveraging closed coal mines for photovoltaic installation plants presents an opportunity for social, environmental, and economic development while creating new job opportunities in emerging renewable energy sectors.

- Aspects like the existence of Interconnection Points could contribute to reduce costs, or timing in executing projects; also, the needs of restoring lands could facilitate permits or licences related to the use of lands for PV projects.

2.3.- Wind power deployment

The wind energy sector is constantly growing and therefore has a positive influence on the European economy. This is reflected in economic growth and the creation of sustainable jobs. As a result, wind energy is particularly popular in research and the optimization of associated processes is constantly being promoted. This includes not only the technology that is used, but also the characterization and distribution of wind energy.

In order to undertake the integration and installation, the associated advantages and disadvantages of this resource are of importance: clean energy, low operating and efficiency costs, as well as high market potential, saving water and creating jobs. The disadvantages in turn are ranging from the specific local conditions, nature and animal protection, the shadow flicker phenomenon and the reliability of the wind resource itself. Apart from that, the demand for rare earths for the production of wind turbines is rising and exceeding existing reserves, while imports and dependencies increase to meet climate goals and a green transition. The planning and approval of such processes are laid down in law. For example, the following aspects must be considered: avifaunistic assessment, noise assessment, shadow assessment, turbulence assessment and geotechnical report.

This report considers the employment effects related to wind energy; the entire value chain of projects for the installation and use of wind power (extraction and processing of raw materials, associated equipment construction and logistics); and project planning and installation. In any case the maintenance and operation, energy delivery, repowering and, after the end of the term, decommissioning and subsequent recycling is needed. Finally, some successful application examples for wind turbines on heaps follow, both in former and still active mining locations. Some of these post-mining examples can be found in Germany, such as the Hoppenbruch heap in the city of Herten in the Ruhr area. However, European heaps largely have one thing in common: their material is often too soft to withstand a superstructure and as a result requires soil improvement and support structures to ensure buildability of wind turbines.

The lessons relevant to GreenJOBS from the deployment of wind power energy can be summarised as follows:

- Russia’s war against Ukraine has exposed Europe’s dependence on fossil fuels and, alongside the climate crisis, poses another important reason for independence through the promotion of renewable energies such as wind power. This needs to be pushed forward as soon as possible, including the former European coalfields for the conversion and new use of closed mines and existing stockpiles.

- To achieve the climate goals and the expansion of wind power, an increase in demand of between 2 and 15 times the current level can be expected. Many of the materials needed are, among others, rare earth, which are mainly found in China. Here a 15-fold increase in demand for rare earth, which are irreplaceable for the construction of plants, can be calculated. This already exceeds the availability for the entire EU on the market.

- Wind power has many advantages in the assessment: clean energy, renewable resource, operation costs close to zero, cost-effectiveness, technological advances benefit falling prices by 80% since 1980 and are expected to further decrease, development in design optimisation, the market potential is rising, wind power saves water compared to traditional energy production methods, and job growth

- Wind power still has some disadvantages: competition when it comes to low costs with other renewable options such as solar power, locations are mostly remote and this makes a supply in urban areas more difficult, reliability of wind itself, wildlife is often disrupted or endangered by rotor blades, disturbance through the average noise level, and the phenomenon of the shadow flicker is disturbing in urban areas.

- The requirements for legal planning of wind turbines are avifaunistic assessment, noise assessment, shadow assessment, turbulence assessment and geotechnical report. The geotechnical investigation of spoil heaps has determined that most of them have a common problem: The material is too soft to withstand the superstructure and therefore requires supporting structures and soil improvements through upgrading the spoil heaps and deep foundations.

2.4.- Unconventional pumped hydro deployment

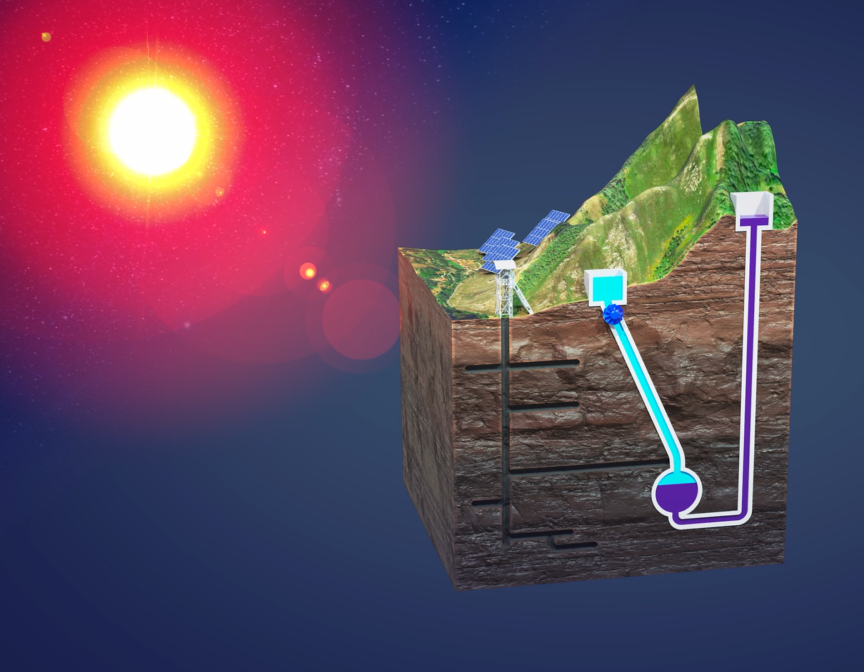

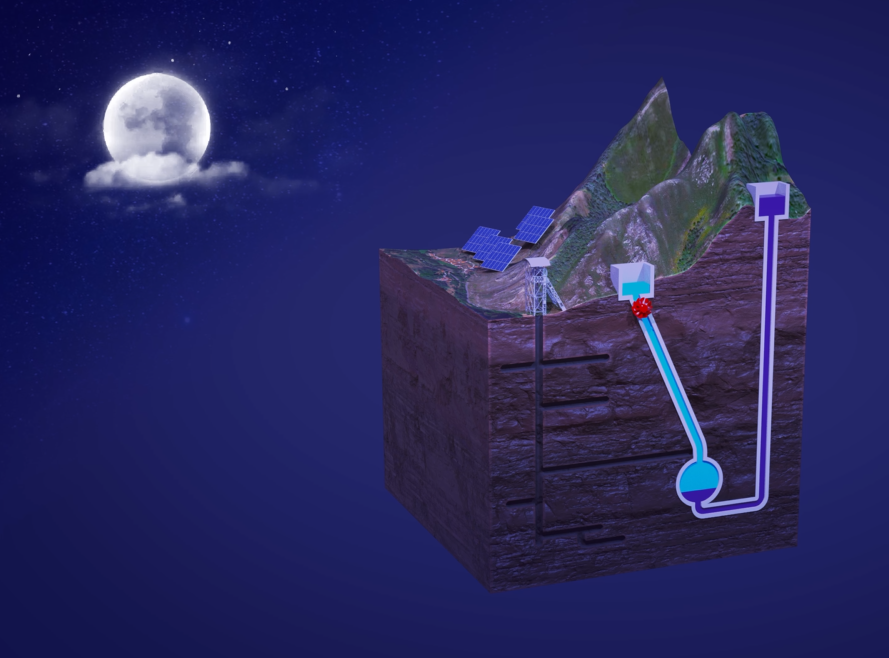

Hydropower in energy generation expansion plays a minor role. However, it has a essential role as an energy storage system, as it can be dispatched when prices are high and, where possible, operated in pumping mode when prices are low. It is an excellent opportunity for Spain, which is on the verge of becoming the first developed industrial country to have a power system dominated by photovoltaic, and to a lesser extent, other non‐dispatchable technologies with zero variable cost, something that starts to be shown in its prices.

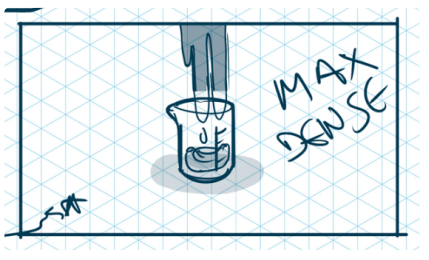

Unconventional pumped hydro storage characteristics are presented according to patent nº WO 2019/202456 A1 (2019) that is the property of one of GreenJOBS partners: Magellan & Barents, S.L.: Upper and lower reservoirs within mining embodiments; penstock portions; high-density fluid to be used based on slurry mixtures; surfactants that should be added to prevent freezing of the slurry; etc.

Unconventional pumped hydro storage features in a mining area are pointed out using the example of the Nicolasa mine in Asturias, Spain. Conditions appear extremely attractive for a first‐of‐a‐kind project: Lithology and topography are favourable. A massive formation of quarzitic puddingstone with high strength and low permeability runs for 800 meters along an escarpment. On the other hand, the mining infrastructure allows inspection of the cavern and even rock removal for additional capacity, with existing conveyor belts in working condition. Dense fluid materials are available and can be sourced nearby as the suitability of materials from a nearby coal-washing installation was validated.

D2.4 Unconventional pumped hydro deployment

The lessons relevant to GreenJOBS from this deliverable can be summarised as follows:

- When wind power and especially photovoltaic become dominant, their daily generation patterns will induce volatile prices, with a long valley at daylight hours (which happen to be peak hours for power demand) and two price peaks before sunrise and after sunset when PV capacity falls sharply (somewhat paradoxically as both price spikes usually take place when demand is at a minimum).

- Photovoltaics and wind power are causing energy storage to become a critical part of the energy transition because photovoltaics and onshore wind power are achieving cost leadership among all power generation technologies. Simultaneously, they depend highly on nature, which is undependable or unreliable at best.

- While conventional hydropower systems stabilise the imbalances of supply and demand, which are inherent in photovoltaic and wind power, at the same time, the footprint required by the reservoirs is high. For its part, unconventional pumped hydro storage is directed to a small footprint, a method with high power output as this system uses high-density fluids that allow for a given reservoir or tank volume, an energy storage capacity proportional to the density of the fluid.

2.5.- Batteries deployment

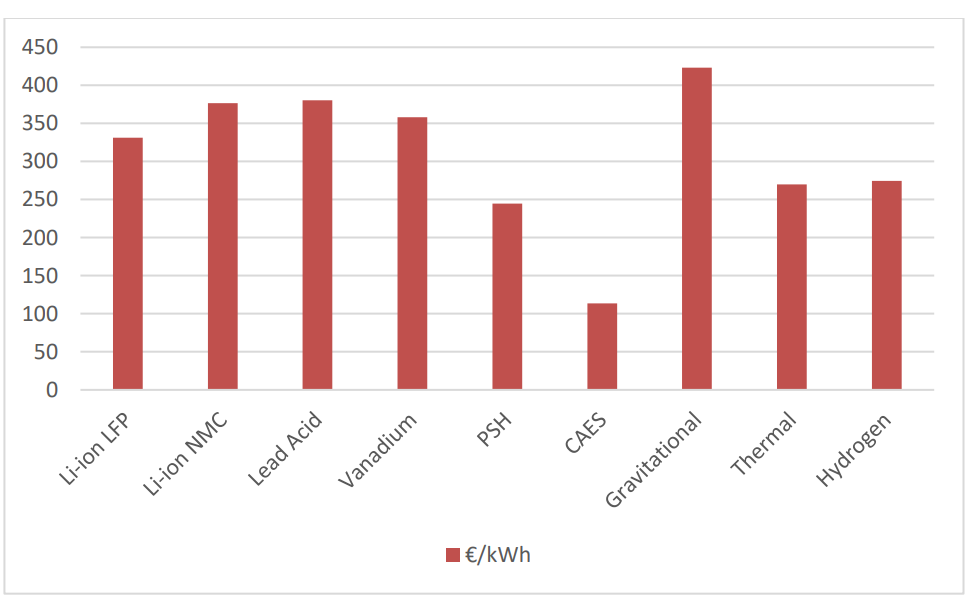

Diabatic compressed-air energy storage (CAES) is estimated to be the lowest-cost storage technology on an installed cost basis at durations equal to or bigger than 4 hours and 100 MW. Something similar happens with other technologies, such as Pumped storage hydropower (PSH). Indeed, no storage technology different from batteries is used when considering 10 MW.

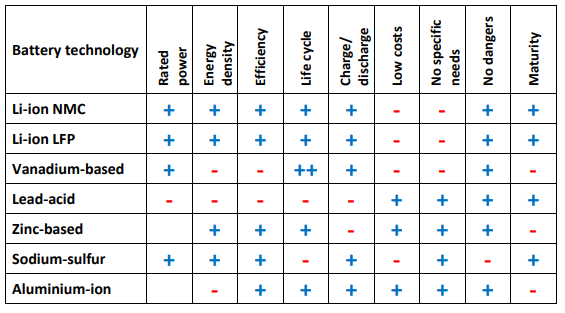

Li-ion batteries are the most exciting technology. They consist of a battery based on charge and discharge reactions from a lithiated metal oxide cathode and a graphite anode. Lithium-ion batteries are used in various ways, from electric vehicles to residential batteries to grid-scale applications. They have high energy densities, high efficiency and a long life cycle, although with high production costs and require special charging circuits. There are two more commonly used lithium-ion chemistries: Nickel Manganese Cobalt (NMC) and Lithium Iron Phosphate (LFP).

The one selected between NMC and LFP will depend mainly on the price. This aspect is analysed when identifying the best technology for mining areas, as well as the operational requirements of the selected technology.

The lessons relevant to the Project from this deliverable can be summarised as follows:

- Diabatic compressed-air energy storage (CAES) is the most economical energy storage system for 10 hours and 100 MW. It is followed by Pumped storage hydropower (PSH) and Thermal energy storage, predominantly molten nitrate salt. However, other storage media, such as crushed rock, sand, concrete, brick, or cast iron, can be considered.

- When requiring energy storage for less than 4 hours and around 10 MW, only batteries are considered and used as feasible energy storage system.

- Currently, Li-ion batteries are the most exciting energy storage system to be used for 2 hours and 10 MW. According to the price, Lithium-ion Iron Phosphate (LFP) batteries are the most interesting, as they are more than 10% cheaper than Lithium-ion Nickel Manganese Cobalt (NMC).

- The rest of characteristics of LFP and NMC are quite similar: rated power, energy density, efficiency, life cycle, charge/discharge, specific needs, dangers and maturity.

2.6.- Green Hydrogen Deployment

Hydrogen has the potential to provide safe, economically competitive, environmental friendly and emission-free energy, but its current penetration in the energy sector is still limited. Hydrogen has the potential to replace fossil fuels in the main areas of energy consumption, including, industrial, transport and, even, buildings sectors, making it a competitive and complementary solution to electrification to achieve a future without emissions. It can cover the energy needs of these sectors even when they are large, require seasonal storage or do not admit electrification.

Hydrogen can compensate for the intermittency of renewable energies by acting as a transportable energy carrier and storable in the gas infrastructures that already exist in most developed countries. Therefore, it is important to assess the storage capacity of the existing gas transmission network and the modifications needed to accommodate to hydrogen or to hydrogen combined with natural gas. Therefore low-carbon hydrogen is a part of the different national plans that form the EU hydrogen strategy and in line with the European Green Deal as the most important document for the decarbonisation of the EU economy by 2050.

D2.6 Green Hydrogen deployment

The lessons relevant to the Project from this deliverable can be summarised as follows:

- The production of hydrogen via electrolysis is expensive. Economic assessment developed for the purpose of this study showed that the investment is not feasible unless a specific subvention is obtained for developing the Green hydrogen plant.

- This aligns with the 50% subvention given by the Big Ticket call for proposals within the Research Fund for Coal and Steel (RFCS).

- Although it is currently in a very incipient phase, the rapid development of the technology of the green H2 will allow its jump to the commercial phase in a short space of time. This combination of processes brings environmental benefits of great importance for the area both by the absence of pollution and by the reduction of emissions of CO2 expected.

3.- Deploying circular economy technologies

3.1.- Dense fluids for pumped hydro

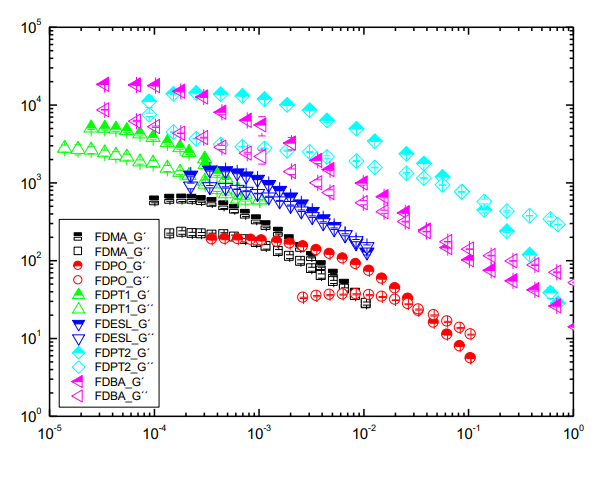

The development of dense fluids required for unconventional pumped hydro by means of using fine coal waste from the three case studies of the project was analysed. The characteristic to be sought is a dense fluid with a density up to three, in order to achieve a yield up to three times that of the conventional pumped hydro.

To achieve this goal, rheology studies consisting on determining the stationary viscous and linear viscoelastic responses of the samples were developed. The rheometric test was specifically designed to obtain the stationary viscous response of the samples under study. The ability of the samples studied to dissipate and store the energy supplied to them, i.e. the determination of their viscous and elastic components, was obtained by performing an oscillating shear rheometric test (also known as mechanical-dynamic analysis). The viscoelastic study was carried out to determine the characteristic time of each sample (relaxation time), which gives an idea of the dominant behaviour (viscous or elastic) depending on the duration of the mechanical action exerted on the material behaviour (viscous or elastic) as a function of the duration of the mechanical action exerted on the material.

Also, the pumping capacities of a high-density fluid material using the finite volume method (CFD) were analysed using ANSYS FLUENT software, version 2021 R1, focused on obtaining the mass flow curves as a function of pressure and pumping head and the maximum pumping head.

D3.1 Dense fluids for pumped hydro

The lessons relevant to the Project from this deliverable can be summarised as follows:

- A small surfactant (less than 1%) should be added to prevent the slurry from coalescing and improve flow. In some cases, antifreeze may be added to prevent freezing of the slurry. The concentration of antifreeze should be sufficient to prevent the slurry from freezing.

- In all cases, in the viscous response and in the range of shear rates that were accessible (reproducible results), it was observed that viscosity decreases with increasing shear rate.

- The viscoelastic study was carried out to determine the characteristic time of each sample (relaxation time), which gives an idea of the dominant behaviour (viscous or elastic) depending on the duration of the mechanical action exerted on the material behaviour as a function of the duration of the mechanical action exerted on the material. This study is defined in the linear viscoelastic response region.

- The results of the fluid-dynamic analysis, in conjunction with the rheology test data, show the pumping capabilities of the high-density fluid, particularly in the upward direction.

- The dumpsite minerals from the mines are initially attractive as base materials for dense fluids. The samples from Slovenia and Spain show values in the interval bounded by our contrast formulations, which have already been used to prepare dense fluids. The sample for Poland is out of bounds but might also be helpful.

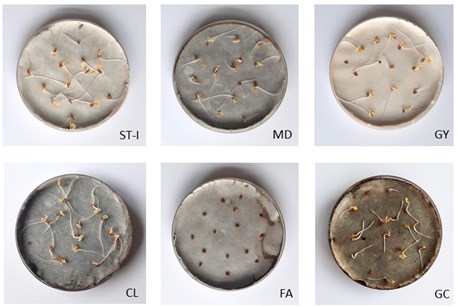

3.2.- Soil substitutes for restoration

Artificial soil substitutes for land reclamation of coal mine-affected areas in the northeastern region of Slovenia (Velenje), were prepared based on by-products from lignite coal combustion: fly ash, gypsum from desulfurization, and sludges from technological water. The components’ high pH, high salinity and low organic matter level are responsible for the lack of plant sproutings.

To improve the conditions for plant growth, lignite coal and green compost from biological manufacturing were tested as additives to the mixture. The optimal composition of artificial soil was developed based on the results of the physicochemical and phytotoxicity analyses.

Sufficient plant growth was obtained; however, concentrations of some toxic metals could slightly exceed warning values according to the regulations in the Republic of Slovenia (As, Cd, Mo and Zn). An additional review of the local laws has to be done to ensure that final products can be used in the reclamation processes.

Based on the results of the physicochemical analyses and phytotoxicity test, the possibility of using mining water from the Premogovnik Velenje coal mine to irrigate vegetation was confirmed. However, salinity and the concentration of molybdenum in that water slightly exceed the recommended threshold for prolonged irrigation use. The concentration of soluble salts and molybdenum and the possible toxic effects on plants and soil organisms should be monitored in areas where long-time irrigation was applied.

D3.2 Soil substitutes for restoration

The lessons relevant to the Project from this deliverable can be summarised as follows:

- Due to its high organic matter content, coal lignite from Premogovnik Velenje Coal Mine is a valuable component of soil substituent. However, to improve soil characteristics such as texture, fertility, water-holding capacity and structure, it is essential to apply other organic materials in the form of ecologically friendly compost from a biological manufacturing process.

- Before developing soil substitute mixtures, exploring the local market for suppliers of green compost, a material rich in organic matter and low content of toxic metals, is essential.

- The most critical parameters for the water extract of tested components can be limited to pH, electrolytic conductivity, primary ions and main heavy metals.

- Industrial products and organic waste with the lowest possible pH and electrolytic conductivity should be qualified for further testing and analysis.

- Fly ash is the most harmful component of stabilizat for germination and plant growth. For this reason, it is essential to avoid raising its amount for soil substitute production.

- Mine water is suitable for periodic vegetation irrigation in post-mining reclamation areas.

3.3.- Recovery of rare earths

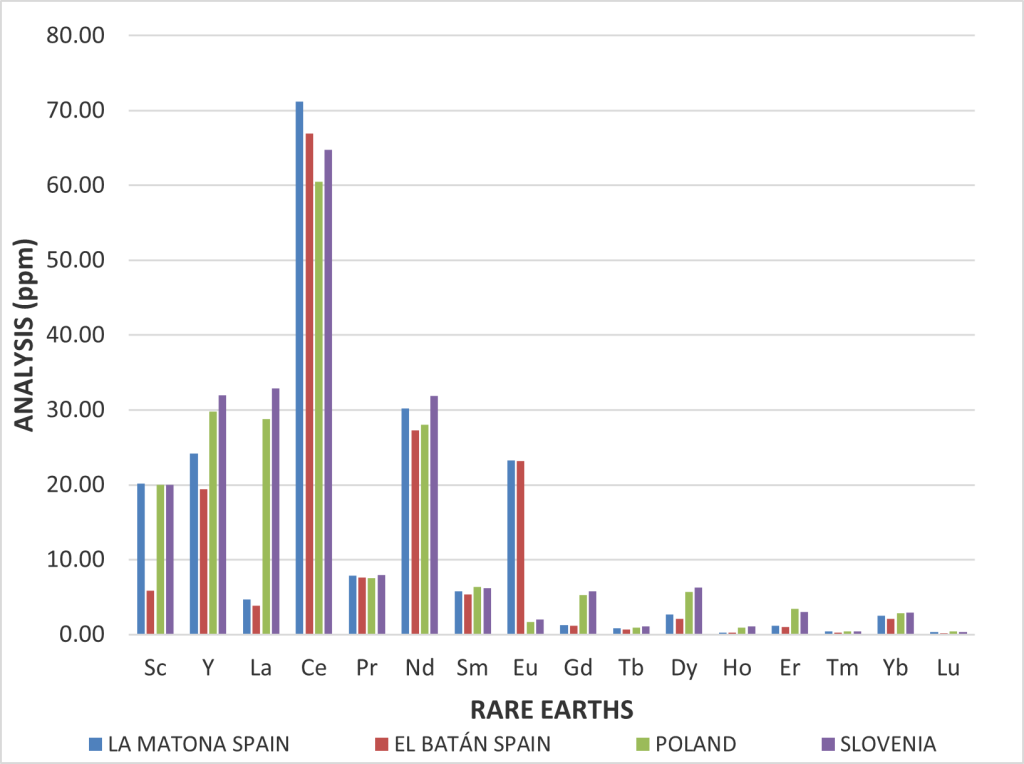

The purpose of this work was to identify potential approaches for the concentration of mixed rare earth oxides from fine coal waste from the three case studies: Spain (HUNOSA), Poland (WEGLO), and Slovenia (PV).

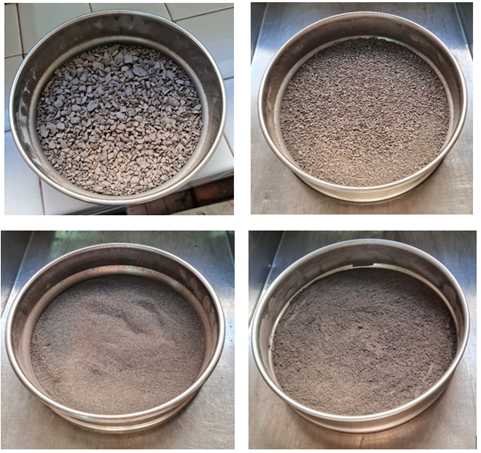

The samples were first be divided into different particle size fractions >2.0 mm, 2.0-0.5 mm, 0.5-0.1 mm, <0.1 mm, because these are the sizes that would be obtained at various process points in the coal washing plants. Subsequently, laboratory analysis were developed for each fraction to identify rare earth contents and the mineralogical species present. The methods used were the Inductively Coupled Plasma-Atomic Emission Spectrometers (ICP-AES) and the X-Ray Fluorescence (XRF).

With the data obtained, rare earth release and concentration analyses were carried out to decide the particle sizes that will allow a higher recovery of rare earths.

Next, since almost all rare earth minerals are very dense, gravimetric concentration analysis was developed in the first place to obtain a dense wet concentrate. The equipment used depended on the liberation analysis: multigravity separator for sizes <0.1 mm, shaking tables for sizes between 0.1 and 0.5 mm, and pulsation box for sizes between 0.5 and 2.0 mm.

Secondly, based on the paramagnetic character of rare earth minerals, the dense concentrates were subjected to high field strength magnetic separation, using a dry route for particle sizes >0.1 mm.

Next, and based on the non-conductive character of most rare earth minerals, a high voltage electric field separation (30-40 kV) was carried out for particle sizes between 0.1 and 0.5 mm (dry route).

Finally, a froth flotation test for particles >0.02 mm was also carried out.

The lessons relevant to the Project from this deliverable can be summarised as follows:

- Initial preparation of samples usually requires between 3 and 15 days to dry at laboratory temperature, so the next steps could follow.

- The initial analysis of the samples revealed that quantitative analysis of elements gives much more representative data than the analysis of compounds, due to the detection limits of the chosen analytical methods.

- There are slight differences between the results of the initial samples and the different particle size fractions. They should be due to the fact that no sampling analysis were made with the initial samples.

- The rare earths concentration is very similar in the three countries analysed. However, El Batán sample from Spain, which has a high content in coal, has a significative concentration of Ytterbium (Yb) and in Praseodymium (Pr), while a lower concentration of Scandium (Sc), Yttrium (Y), Neodymium (Nd) and Samarium (Sm).

- Since the analyses performed show very similar rare earth concentrations in the three countries considered, only the possibilities of rare earth concentration in the two Spanish samples were studied in detail. The results are expected to be mostly extrapolated from one waste to another.

- Pulsation box gravimetric concentration tend to concentrate rare earths in the denser fractions, but nothing really significative.

- High field strength magnetic separation seems to be the only concentration method that allows a higher recovery of Scandium (Sc), Yttrium (Y), and Cerium (Ce), but only within the fraction 0.1 – 0.5 mm.

- Rare earth concentrations obtained from analyses range from 150-310 ppm, which is around 0.015-0.031%. For a mine to be mineable, concentrations between 1 and 2% are required. This gives an idea that the amount of rare earths present in the tailings dumps in the three countries (Spain, Poland and Slovenia) is too low to be economically viable for exploitation.